Inside Our Factory

With over 28 years of specialized experience in the printing and gaming industries, our facility is a global leader in the manufacture of high-quality custom card games, puzzles, and board games. We operate out of a vast 13,000-square-meter plant, combining the experience of 300+ professional personnel with the precision of 30+ modern production machines. We maintain a simplified process with over ten dedicated production lines, resulting in a monthly capacity of 800,000 pieces. This combination of long-standing tradition, large-scale infrastructure, and high-volume output enables us to provide our global partners remarkable dependability, competitive lead times, and uncompromising product quality.

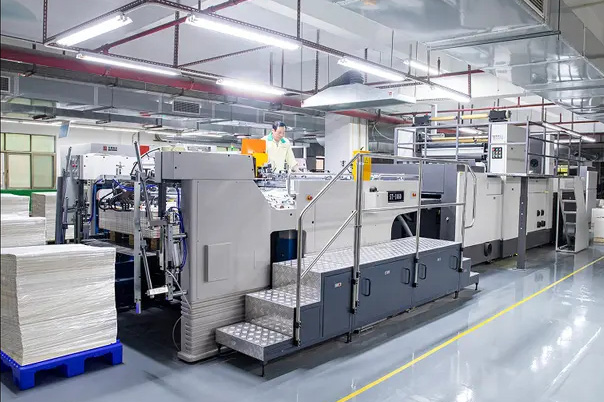

Our Facility Unveiled

We provide a high-precision production platform for tabletop games, puzzles, and cards. We use AI-calibrated Heidelberg printing with CCD-guided automation (±0.05mm precision) to provide 100% color accuracy and smooth component fitment. From professional "Air-Cushion" card graphics to high-density puzzle precision and robust board game packaging, we have the technological foundation to transform difficult designs into masterpieces.

Using Heidelberg Speedmaster presses with Inpress Control, we ensure 100% color consistency and UHD clarity. Our professional-grade offset printing eliminates batch variation, bringing your designs to life on premium substrates.

To ensure durability and a premium feel, we use advanced UV coating, embossing, and thermal lamination. From "Air-Cushion" textures to scuff-resistant finishes, our technology delivers rich colors and tactile quality meeting international standards.

We use high-speed automated lines with CCD optical alignment and precision dies to maintain a ±0.05mm tolerance. This real-time inspection eliminates errors, ensuring burr-free edges and a consistent, smooth shuffle.

How We Turn Ideas into Tabletop Reality

Merging Heidelberg precision with our 10-step workflow, we craft games and puzzles that captivate players worldwide.

Quality Assurance Program

Material Standards

Quality begins at the source. We use only FSC-certified paper, soy-based inks, and non-toxic materials (EN71/ASTM/CE). This strict selection ensures every deck and puzzle meets the highest standards for safety, durability, and premium feel.